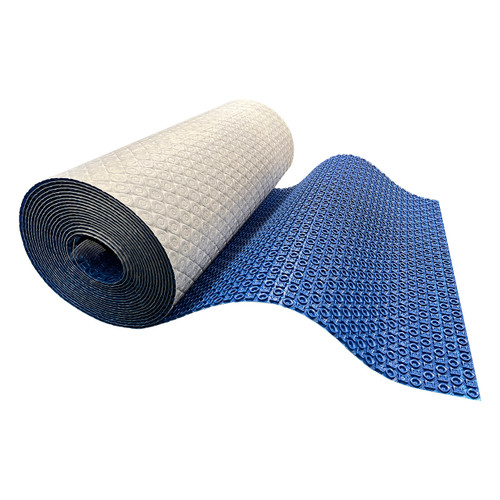

Mapei Mapeheat Membrane Maxi - Heating Cable Carrier Mat - 10m

Mapei Mapeheat Membrane Maxi - Heating Cable Carrier Mat - 10m

The waterproofing, uncoupling, anti-fracture, heating system. Lightweight uncoupling, crack-isolation and waterproofing membrane for electrical floor heating.

The waterproofing, uncoupling, anti-fracture, heating system. Lightweight uncoupling, crack-isolation and waterproofing membrane for electrical floor heating.

ADVANTAGES:

- Suitable for multiple size cables: diameters from 2 to 5.5 mm

- Thin profile

- Helps prevent transmission of in-plane substrate cracks (cracks width: up to 3 mm)

- Minimal roll memory for faster installation

- Heating cable installs easily, and lays flat and secure

- For the installation of ceramic tiles the use of minimum class C2 adhesives (in compliance with EN 12004) is recommended (to be chosen dependently from the tile size)

DESCRIPTION

Mapeheat Membrane Maxi is a lightweight uncoupling, anti-fracture and waterproofing membrane for electrical underfloor heating. This patented membrane is designed to speed up the installation of tile and stone in interior rooms such as bathrooms, kitchens and living areas where the luxury of radiant floor heating is desired.

Mapeheat Membrane Maxi's thin profile works well with remodelling projects where the new floor will be installed directly over a pre-existing one. Once the heating cable is set within Mapeheat Membrane Maxi's reliefs, a tile adhesive or levelling/smoothing compound can be applied immediately.

WHERE TO USE

- Use under ceramic, porcelain and natural stone tiles in interior residential spaces such as kitchens, bathrooms, shower floors and living areas.

- Use as a substrate to receive smoothing compound prior to installing engineered wood, luxury vinyl tiles, luxury vinyl planks, laminate flooring and mosaic tile.

Some application examples

For the installation of Mapeheat Cable heating over:

- Concrete cured for a minimum of 6 weeks.

- Sand:cement screeds cured for a minimum of 7 days and capable of supporting tile installation traffic without leaving any indentations.

- Tile adhesives and smoothing compounds.

- Tile backer boards – see manufacturer’s installation guidelines.

- Exterior grade plywood at a minimum thickness as outlined in the local standards.

- Existing, well-bonded ceramic tile and dimensionally stable natural stone.

- Existing, firmly bonded luxury vinyl tiles.

- Existing cement terrazzo floors.

Consult MAPEI’s Technical Services Department for installation recommendations regarding substrates and conditions not listed.

APPLICATION PROCEDURE

Preparation of the substrate

- All suitable substrates must be smooth, structurally sound and free of any contamination that could prevent or reduce proper bond and/or affect product performances.

- When applying moisture-sensitive floor coverings such as engineered wood or luxury vinyl tiles, in areas with high levels of moisture, a suitable MAPEI surface membrane, such as Mapeproof ESM and a suitable MAPEI cement based smoothing compound should be applied prior to installing Mapeheat Membrane Maxi.

- Calcium sulphate screeds must be dry to a moisture content of 0.5% w/w when measured using the carbide method. All surface laitance must be removed by mechanical abrasion and all dust thoroughly removed by vacuum. Prime the surface with Eco Prim T Plus (diluted 1:2 with water) or alternatively Primer G (neat).

- Cementitious substrates must be cured and any shrinkage process must be at an end before tiles are installed. Concrete should be cured for at least 6 weeks, cement-based screeds for at least 7 days unless they have been produced using the special MAPEI binders Mapecem or Topcem or with a pre-blended screed mix such as Mapecem Pronto or Topcem Pronto. The substrate surface should ideally be open textured. Power floated concrete should be mechanically abraded (scabbled or shot-blasted) to open up the surface and to remove any curing agents.

Applying the product

- Read all installation instructions thoroughly before installation.

- Apply Mapeheat Membrane Maxi when substrate and ambient temperatures are between +10°C and +35°C.

Bonding Mapeheat Membrane Maxi to the substrate

- Select an appropriate MAPEI C2 classified adhesive such as MAPEI Keraquick S1, Ultralite S1 or better.

- Pre-cut and dry-fit Mapeheat Membrane Maxi in place and then set aside.

- Apply the adhesive to the substrate. If the substrate is existing tile, stone, luxury vinyl tiles or terrazzo, prime the surface using MAPEI’s Eco Prim Grip Plus before applying the adhesive.

- Lay the previously cut portion of Mapeheat Membrane Maxi over the wet adhesive, fabric side down.

- Lay the next sheet of Mapeheat Membrane Maxi, taking care to align it with the previous sheet. Ensure that all reliefs align to the previous installed sheet and that sheets do not overlap each other.

- To ensure a full bond between Mapeheat Membrane Maxi and the substrate, use a weighted roller over the installed membrane. For smaller pieces of membrane, use a wood float, steel trowel or hand roller to apply pressure.

- After rolling, the applied membrane , clean off any excess adhesive that may have squeezed up through the seams between the membrane sections.

- Allow the adhesive to cure.

Waterproofing (optional for installing ceramic tile)

- After the cable has been properly installed, Mapeguard WP Adhesive over. Over the adjoining seams using the flat side of a trowel. Be sure to fill in any holes or voids, taking care not to damage the heating cable with the trowel.

- Bond Mapeguard ST or Mapeband Easy jointing tape into the wet applied compound, ensuring an overlap of 50 mm each side of the seam.

- To waterproof around the walls of the installation area, take a pre-measured length of the joining tape and fold it in half along its length. One side of the fold will be adhered to the floor, and the other side will be adhered up the wall. To accomplish this, follow the installation methods detailed in steps 1 and 2.

Installation of ceramic/porcelain tile and stone

- For regular installations, utilise the same adhesive used to bond Mapeheat Membrane Maxi to the substrate (minimum of C2 S1 classified tile adhesive). For fast-track installations, bond tiles with one of MAPEI’S rapidsetting tile adhesives such as MAPEI Keraquick S1.

- Mix the selected adhesive at the top end of recommended water ratio as outlined on the packaging.

- Using the flat side of a trowel fill the cavities of Mapeheat Membrane Maxi with adhesive or alternatively, a rubber grout float can be used.

- Where mosaic tiles are to be installed apply a suitable Mapei smoothing compound, such as Ultraplan Renovation Screed 3240 to a minimum depth of 6mm before installing the selected mosaics.

- Use the trowel’s notched side to apply adhesive over the prefilled Mapeheat Membrane Maxi. Spread only as much adhesive as can be covered before the adhesive skins over. Open times vary with jobsite conditions and adhesive choice.

- Begin to install the tile/stone. Occasionally remove a tile to ensure full coverage is being achieved

- For waiting times before grouting and protection from light foot traffic, refer to the TDS’s of the MAPEI tile adhesive and grout used. Depending on site conditions, tile size, temperature and humidity, waiting times may need to be extended.

- When cleaning out grout joints before grouting, be careful not to damage the cables that may be underneath.

Wait a minimum of 7 days after the completed installation of tile before reactivating the heating cable.

Installation using a smoothing compound and of alternate floor coverings (engineered wood, luxury vinyl tile, luxury vinyl plank, laminate)

- Priming of the Mapeheat Membrane Maxi is not required prior to the application of smoothing compound.

- Apply a suitable MAPEI Ultraplan Renovation Screed 3240 over Mapeheat Membrane Maxi at a minimum thickness of 6 mm above the highest point of the membrane. Conformation should be sought from the floor covering manufacture as to the minimum thickness of smoothing compound required prior to the installation of the intended floor covering.

- Allow the applied Ultraplan Renovation Screed 3240 to cure.

- Install floor covering using an appropriate Mapei adhesive relative to the selected floor finish.

Note: Tile/stone is the most efficient floor covering for providing maximum heat conductivity and thermal output per square meter. As other floor-covering types may not transfer heat at the same rate, they may not warm the floor to the same degree as ceramic tile and stone will.

Caution: The technical data sheet and/or installation instructions for any chosen floor covering must confirm compatibility with radiant floor-heating systems. In addition, the temperature of the heating cable must not exceed the floor covering’s maximum allowable temperature.

FOR APPLICATION PROCEDURE PLEASE DOWNLOAD THE TECHNICAL DATA SHEET, OR DISCUSS WITH MAPEI TECHNICAL, OR PURE ADHESION LTD